Services / Equipment

Services

Our Services

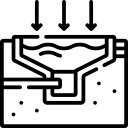

Clarification and Thickening Systems

Our clarification and thickening systems are designed to efficiently remove solids from wastewater. We provide a complete line of components, including clarifiers, thickeners, and our innovative retrofit scum skimmers for optimal performance and reliability in various treatment processes.

Screening and Filtration

Drive and Mechanical Systems

Our drive and mechanical systems provide reliable operation for your water treatment processes. We specialize in clarifier and thickener drives, rotary distributors, and trickling filter systems that allow for seamless performance and durability in demanding environments.

Digestion and Mixing Systems

Fiberglass Products

Our Equipment

Trucks / Cranes / Trailers

- #32 – 2011 Chevrolet Silverado Service Truck with misc. tools

- #39 – 2011 Chevrolet Silverado Service Truck with misc. tools

- #40 – 2010 Ford F350 Super Duty Crew Cab Utility Truck with welder and misc. tools

- #41 – 2010 Ford F350 Super Duty Crew Cab Utility Truck with welder and misc. tools

- #46 – 2007 Chevrolet Silverado Service Truck

- #47 – 2007 Chevrolet Silverado Service Truck

- #48 – 2007 International 4200 Utility Truck with

- #45 – 2006 International 4200 Utility Truck with

- #43 – 2002 International 4600 Flatbed Crane

- #50 – International 40 Ton Crane

- #36 – 1994 International Utility truck with three welders, 5ton Crane

- #35 – 1993 International Utility truck with two welders/generators

- #51 – Mack 14 Ton Crane

- #44 – International 4600 Vactor

- 1981 Freightliner 80,000# GVW Tractor Trailer

- 1974 International 80,000# GVW Tractor Trailer

- 48 ft. flatbed trailer for 80,000# GVW tractor trailer.

- 40 ft. flatbed trailer for 80,000# GVW tractor trailer.

- 30 ft.1 35 ton capacity low-boy trailer for 80,000# GVW tractor trailer

- 35 ft. flatbed tilt trailer with 50,000# capacity.

Forklifts / Loaders

- 20,000# Capacity Pettybone Fork Lift with Riggers Boom.

- 10,000# Capacity Yale Fork Lift.

- 4,000# Capacity Clark Fork Lift with Triple Mast and Riggers Boom

- 4,000# Capacity Clark fork lift.

- 4,000# Capacity Electric Tight Quarters Fork Lift.

- Case 680 CK Frontend Loader/Backhoe

Machine Shop Equipment

- 28” x 120” Sydney Lathe.

- 30” x 80” American Lathe.

- 30” x 144” American Lathe.

- 60” x 60” Bullard Horizontal Boring Mill.

- 48” Bridgeport Vertical Milling Machine.

- 48” Index Vertical Milling Machine.

- 24” Radial Drill Press.

- 36” Radial Drill Press.

- 48” Radial Drill Press.

- 48” Index Shaper with 14” stroke.

- 50 ton capacity bearing press.

- 60” Horizontal milling machine with vertical mill adapter.

- 14” x 60” Rockwell Lathe.

- 16” x 60” Turret Lathe.

- 36″ x 244″ Baer and Emmes Lathe

Pumps

- 14” x 16” 7.9 MGD 250 HP electric pump

- 6” 30 HP Flygt submersible electric de-watering pump.

- 6” 20 HP Flygt submersible electric raw sewage pump.

- 4” 10 Hp Flygt submersible electric pump.

- 4” 5 HP Flygt submersible electric de-watering pump.

- 4” 5 HP gould submersible electric raw sewage pump.

- 4” 3 HP 3 Phase Enpo Cornel Cutter/Grinder Pump.

- 4” 3 HP 1 Phase Empo Cornel Cutter/Grinder Pump.

- 3” 3 HP submersible electric pump

- 4” gas driven self priming pump.

- 3” gas driven self priming pump.

- Numerous 1” to 2” submersible electric pumps.

- 40 KW Diesel generator 220 volt, 3 phase.

- 5 KW Diesel generator 220 volt, 3 phase/220 volt single phase

- 10 KW Gasoline generator 220/208 volt, single and 3 phase7 gasoline welder and 4 KW 220/110 volt single phase generators.

Miscellaneous

- Concrete coring equipment to 6”

- 3 – Portable magnetic drills.

- Concrete drilling and jack hammering equipment.

- Concrete drilling and jack hammering equipment.

- 1 – 100 lb. Cap., 2 – 200 lb. Cap., 1 – 300 lb. Cap., 1 – 500 lb. Cap. Sandblaster Pot

Clarifier and Thickener Hot-Bypass Capability

Though the effluent turbidity and sludge density may temporarily degrade during the bypass, this method has been successfully proven in emergency situations and maintenance scenarios. With our Hot-Bypass procedure, we help clients avoid significant downtime while ensuring the continued operation of critical water and wastewater treatment systems.